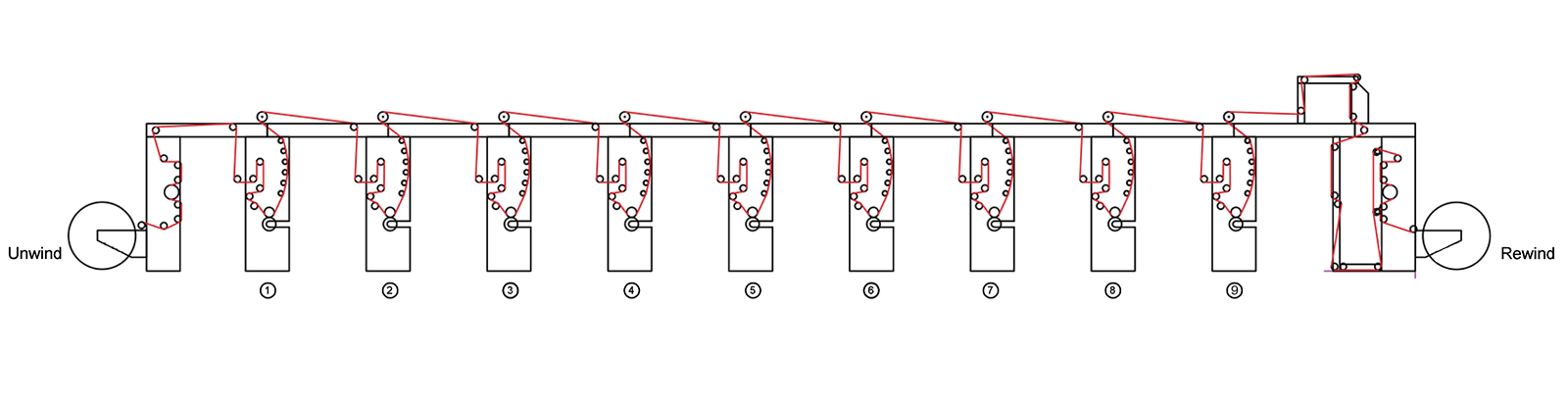

Narendra gravure features among the most advanced rotogravure printing press with MLS technology. With our manufacturing processes being 100% in-house, we boast the ability to provide a solution that is customizable according to the specific needs of our clients. This translates into a highly efficient converting process, reducing variable costs, inventory space and time. Examples of some modifications include - an online lamination unit, or coating unit giving the ability to produce finished goods in a single run.

This machine is specially suitable for customers who are entering a new market. This machine has a low set-up cost up-front. It is equipped to provide reliable long term performance, and can produce high enough volumes to get your converting journey started.

This versatile machine can fulfill the most challenging demands of the converting industry, it is very easy to use and has a low workforce requirement. This machine will help you kick-start your journey for producing multi-layer flexible laminates.

Whether printing on paper, BOPP, polythene, polyester or foil - we are capable of meeting all demands of the converting industry. Our machines are very versatile and can be used for medium to long run lengths.

| Technical Specifications | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||

Ergonomic Mechanical design, with control buttons placed at point of application

Standard features like length counter, dia sensor and job memory functions

Centrally located web video and register control station

Advanced electronics control with SIEMENS drive, HMI, servo motors and PLCs for precise control

All drive synchronized with PLC

Changing doctor blade is a tool less operation

5 axis motion for precise doctor blade setting

Pneumatically operated doctor blade for consistency of job

Optimized design to provide high nozzle velocity and CFM

Pneumatically operated chamber eases web threading and cleaning operation

Dedicated infeed and outfeed for maintaining optimum tension profile

Timing Belt and pulleys ensure noise free and precise operation

All components are made using automated CNC and VMC machines

Main frames made from solid 45mm thick plates

Hardened ground gears for noise free operation and long life

Auto reel changing turret at unwind and rewind

On-line lamination (optional)

On-line coating

Electrostatic assistance

Static eliminator

Ink circulation pump viscosity controller

Automatic print registration