Two in One Coating machine is a revolutionary machine developed by Narendra Gravure. This machine has changed the definition of how 3-ply laminates like: Paper, Foil, HSL are made. Now, 3-ply laminates can be made in a single go, instead of using 2 machines to complete the job. This makes the process highly efficient, saving production time and energy, therefore bringing the variable cost of production drastically down.

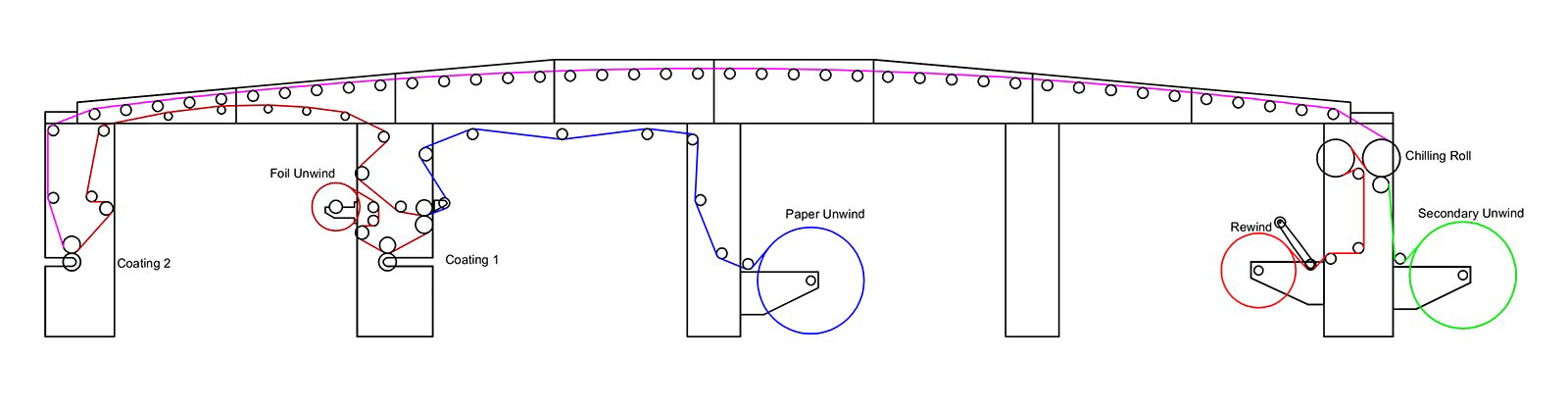

On this machine, first the foil and paper are laminated using a wet lamination process followed by a second registered coating (HSL/Adhesive) on the substrate before it enters the drying tunnel where the laminate is cured. On exiting the drying tunnel, the material can be dry laminated or directly cooled on twin chilling rollers before it is rewound.

This combi machine can also be used for standard dry lamination jobs.

| Technical Specifications | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||||||

Registered HSL coating application with reference to printing

Twin chilling rollers with an “S” wrap maximizes contact area and results in most efficient web conditioning.

Ergonomic Mechanical design, with control buttons placed at point of application

Standard features like length counter, dia sensor and job memory functions

Advanced electronics control with SIEMENS drive, HMI, servo motors and PLCs for precise control

Changing doctor blade is a tool less operation

5 axis motion for precise application

Pneumatically operated doctor blade for job consistency

Long and efficient drying chamber with recirculation, saving upto 50% energy

Optimized design to provide high nozzle velocity and CFM

Pneumatically operated chamber eases web threading and cleaning operation

Dedicated infeed and outfeed for maintaining optimum tension profile

Timing Belt and pulleys ensure noise free and precise operation

All components are made using automated CNC and VMC machines

Main frames made from solid 45mm thick plates

Adhesive circulation pump

Viscosity controller

Auto Reel changing turret

Shaftless assembly for unwind/rewind