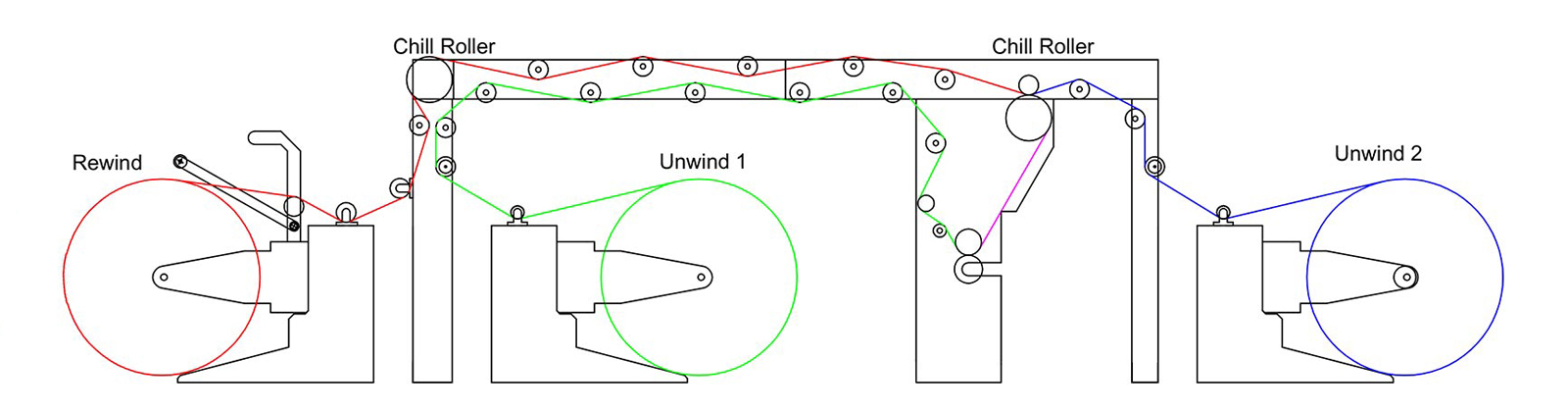

Narendra Gravure developed the Hot melt lamination machine for the application of wax lamination used in manufacturing of induction wads. This machine employs a gravure based transfer technology for transferring of the hot melt on the substrate. The machine comes with a precise temperature controlled premeltor kitchen module - which is very instrumental to maintain a reservoir of a pre-mixed homogenous recipe to have repeatability and reducing job set-up time

The heated tray features 12 heating zones controlled by high density ceramic heaters to ensure a precise and homogeneous temperature control of the tray which eliminates any possibility of burning wax and/or frozen chunks of wax which results in high accuracy and unparalleled quality. Furthermore, the machine features IR heaters, temperature controlled laminating nip and a chilling roller which allows the operator to have 4 distinct and precisely controllable temperature zones enabling a diversity of wax lamination jobs with very high degree of precision and repeatability.

| Technical Specifications | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||||

Shaftless groundlifting unwind and rewind for fast job changeovers

Hydraulically operated lifting and clamping operations

Pre mixture tank and pump are included in the standard scope of supply.

PLC control results in precise operation

Jacketed premeltor tank with agitator maintains uniformity and results in a homogeneous mixture of raw materials

The machine has 4 distinct temperature controlled zones, with precise control setting

Ergonomic mechanical design makes the machine operator friendly and easy to use

Advanced electronics control with SIEMENS drive, HMI, servo motors and PLCs for precise control

Dedicated infeed and outfeed for maintaining optimum tension profile

Timing Belt and pulleys ensure noise free and precise operation

All components are made using automated CNC and VMC machines

Main frames made from solid 45mm thick plates